Product Code: PP292

Peel-off ends has made a more attractive and consumer-friendly alternative to conventional can ends. We provide peel off end for two-piece and three-piece can packing with a flexible, convenient and extremely economical solution and enable our customer products stand out in the market.

Our peel off end is easily used on existing seamers which can be integrated into existing can filling and packing lines.

Applications:

Non-processed foods such as snacks, nuts, powdered beverages, coffee and tea, infant formula, soup and sauce mixes, noodles and rice, spices, pet food and treats; non-food products.

Peel-off ends has made a more attractive and consumer-friendly alternative to conventional can ends. We provide peel off end for two-piece and three-piece can packing with a flexible, convenient and extremely economical solution and enable our customer products stand out in the market.

Our peel off end is easily used on existing seamers which can be integrated into existing can filling and packing lines.

Applications:

Non-processed foods such as snacks, nuts, powdered beverages, coffee and tea, infant formula, soup and sauce mixes, noodles and rice, spices, pet food and treats; non-food products

Reference Picture

Standard Features

1) Used for Metal, plastic and rigid paper cans

2) Ends are able to configure with can size

3) Food grade material

4) Eco-friend Modern

5) High class and attractive out-looking

6) Durable and tamper-resistant

7) Light, recycle, sanitary and convenience packaging form

Optional Features

1) Tab or ring-pull

2) Foil thickness as request, 60-90 micron

3) Smooth or waffle (textured) membrane

4) Full peel off or D shape peel off available

5) Other shape

6) Embossing, Printing, Lithography available

7) Different colors

8) Transparent peel off part

9) Retort able withstand high temperature

10) Compliant with FDA, EU and Chinese GB standards

11) Other type Ends available

12) Relevant seaming machine provided

Reference Pictures:

The Peel off Ends are the most attractive and eco-friendly modern lids for dry food packers especially major milk powder fillers, we are using the latest automatic thermo-sealing technologies machines to ensure the highest standard for our global consumers.

Our quality objective is to improve efficiency and reduce cost through superior product and service. We are committed to the implementation, monitoring and improvement for an effective application for whole can/ Ends manufacturing and canned food packing.

| Shape | SIZE | MATERIAL | Usage | D-Shape Aperture | ||

| Round | Diameter | Steel | ALU | Dry | Retort | |

| 52 | √ | √ | √ | √ | ||

| 55 | √ | √ | √ | √ | ||

| 65 | √ | √ | √ | √ | ||

| 73 | √ | √ | √ | √ | ||

| 83 | √ | √ | √ | √ | ||

| 99 | √ | √ | √ | √ | √ | |

| 127 | √ | √ | √ | √ | √ | |

Technical Specification for Single Ends

| Name | Peel Off End |

| SKU | 5E-POE-**A |

| Size-Diameter (mm) | 52, 55, 65, 73, 83, 99, 127 |

| Recommend Application | Snacks, nuts,coffee, tea, Pet food |

| Membrane Color | Silver, Gold, White |

| Ring Color | N/A |

| Tab | Available |

| Ring-Pull | N/A |

| Aperture Shape | Round/ D shape |

| Membrane Material | Aluminum foil, PET |

| Other Part Material | Aluminum, Tin |

| Membrane Type | Smooth or waffle (textured), Transparent |

| Printing | N/A |

| Liner | Food safe lacquer, EPE liner |

| Min Order | 50,000 |

| Others |

More Options Ends

In order to have suitable size 2-piece can or 3-piece can, following options for your reference.

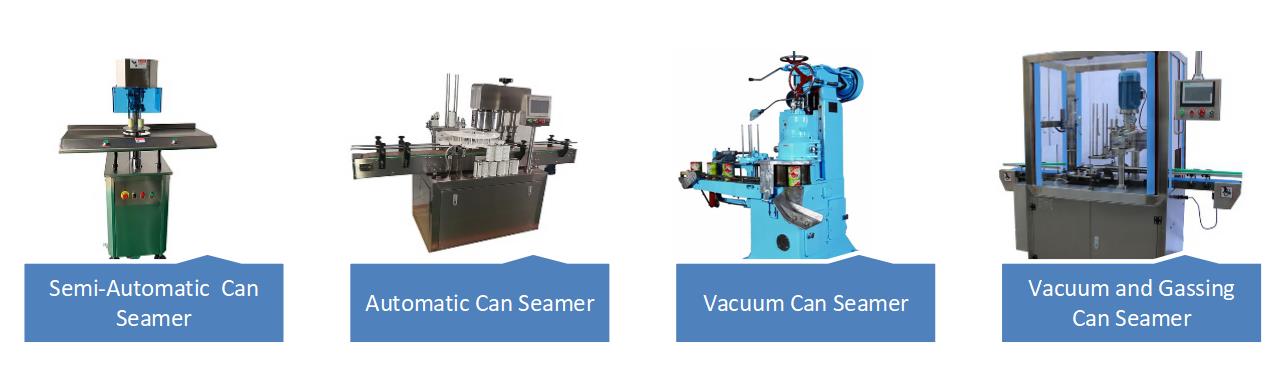

In order to achieve the can seaming process, following are options of can seaming machine